AEM Engine Position Module - Crank/Cam Trigger Idea

Posted: Thu Oct 23, 2014 10:28 am

Has anyone used one of these yet? http://www.aemelectronics.com/?q=produc ... module-epm

It's a crank and cam sensor that replaces your distributor/cam sensor to run wasted spark/COP. They have some generic SBC/SBF distributor applications, but they also have a Honda one that looks like it could be much more universal.

I did find this post, which doesn't have nice thoughts on this kind of setup: http://honda-tech.com/engine-management ... u-2429136/

So, maybe that leads to a slightly different question...would it be safe to run a camshaft driven 'single' trigger on an engine? Is the concern mainly with timing belts, or are timing chains subject to the idea in the thread above?

It's a crank and cam sensor that replaces your distributor/cam sensor to run wasted spark/COP. They have some generic SBC/SBF distributor applications, but they also have a Honda one that looks like it could be much more universal.

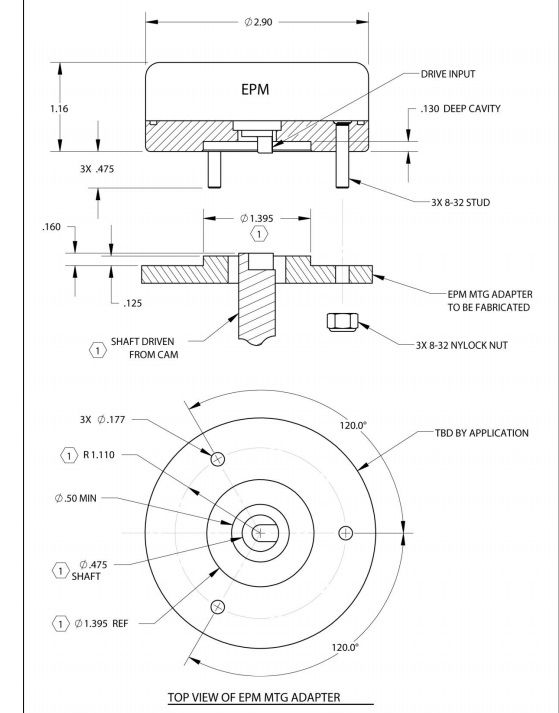

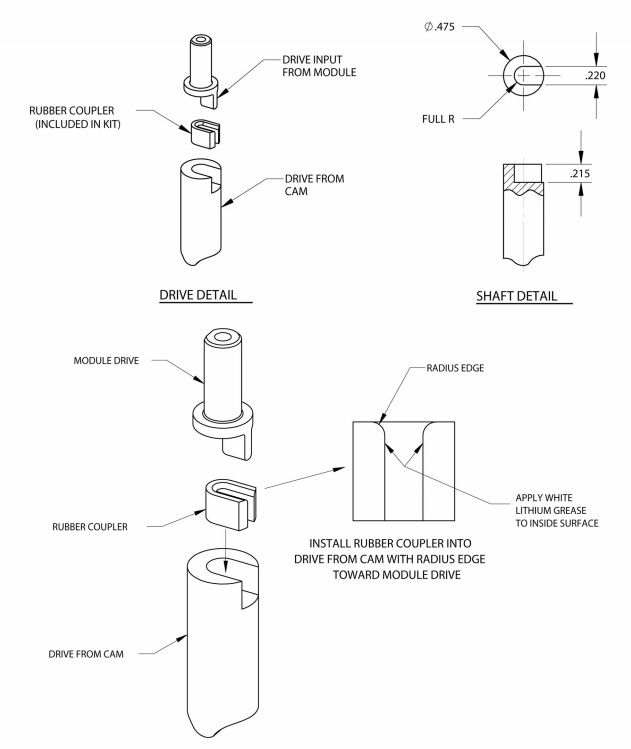

A fellow 190E guy I know plans on adapting on to the 2.3-16 distributor (along with my help), so I was curious if anyone else had gone this route. This seems like it could be a nice solution to the crank mounted trigger (V8's/I5) for those that don't have a flywheel trigger.AEM's EPM provides precise engine position using dual zero-speed optical sensors, which offers the advantage of immediate signal generation regardless of engine speed. The EPM easily adapts to any positive-drive, half-engine speed device such as a cam or distributor drive, and can be used with any aftermarket engine management system that recognizes the common 24 & 1 pattern for crank and cam signals.

Bolt-on systems available for all distributed Chevy small block and big block engines, Ford 5.0L small blocks with EFI (1986-93), Ford 351 Windsor, 289 and 302 small block engines, and Honda B-, D-, H-, and F-series race engines

Very simple four-wire connection for easy installation (12V, ground, crank signal, and cam signal)

Output signal amplitude and waveform stay constant at all RPM

Shock absorbing elastomer drive system eliminates potential for ignition timing deviation and protects the EPM from vibration

24-tooth crank, 1-tooth cam pattern per engine cycle for accurate timing and easy set up (Pattern available in cam/crank sensor wizard in AEMPro/AEMTuner/InfinityTuner)

EPM manufactured from 6061 T-6 billet aluminum

I did find this post, which doesn't have nice thoughts on this kind of setup: http://honda-tech.com/engine-management ... u-2429136/

So, maybe that leads to a slightly different question...would it be safe to run a camshaft driven 'single' trigger on an engine? Is the concern mainly with timing belts, or are timing chains subject to the idea in the thread above?