Wow, sorry! I totally forgot I was going to update this haha. Well, here it goes.

Remember the rusted out rear tail light area? Well, I got to work on that a few weeks ago. It didn't come out as planned, but it was good learning.

Keep in mind, I am making all of these panels by hand without any special tools at all. I got so close to getting this right, but in the end something made one of the edges of the part warp badly. I'm not sure if it was the grinding or warpage during welding.

Here was the start

and here it is after grinding all the welds down. The curved area that faces up toward the sky is pretty badly misshapen. It was nearly perfect before I finished welding and grinding though :( Its OK as it has paint on it for the time being and seals the water out of the trunk well (though there is still one place where it is leaking a very small amount... probably due to a slight bump in the sealing surface somewhere along with old seals. I'll revisit this later to get the shape right so minimal filler will have to be used come paint time.

Since this repair, I decided to step away from the body work and rust repair for a few weeks and get some mechanical work in for a change. I'm almost back to the point where I'm ready to dive into the rust again though

Next on the list was an on board computer (OBC) upgrade for my Dad's E36. His old 11 button version had a messed up screen, so I bought him an 18 button version for Christmas. Little did I know, the conversion isn't so simple if you want to have full functionality, and of course I can't do this without achieving anything but the best I possibly can

Since I knew this was going to be a pretty big job by the time I got started, my buddy Justin and I got prepared the best way we knew how. In the process, we found that the E36 has a nifty beer holder in the glovebox!

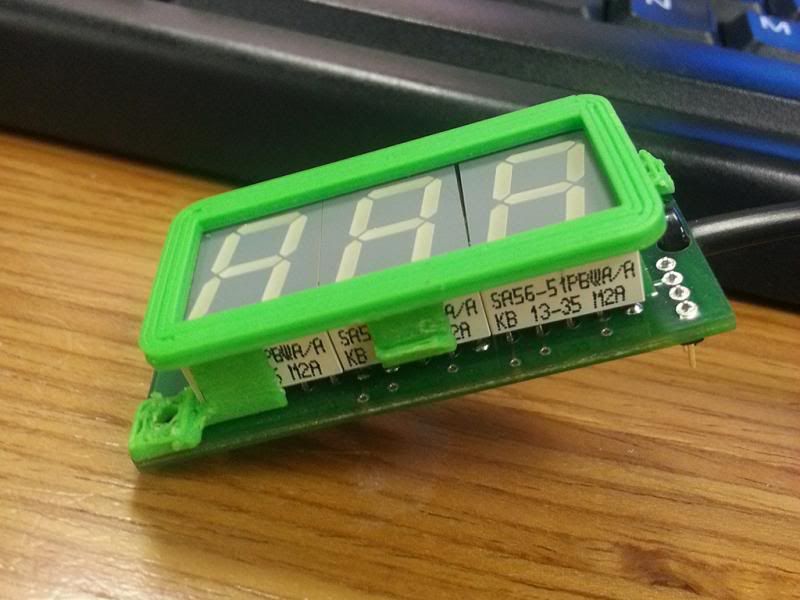

Here's the computer

This was the state of the car about half way through the install.

Eventually we got everything wired up and it all functioned properly the first time we tried it including the CODE function which requires a code to be entered to operate the ignition system of the car. That is usually what people can't figure out and leave unfinished. We also added a blinker stalk which will can be used to scroll through the functions of the on board computer.

Also got a new air vent for the car at the junk yard as the old one was broken somehow.

That wasn't the only thing I got at the yard... I also managed to find BMW fitment spacers. 5x120 31.5mm. Very nice pieces! And they were just hanging out on the car after someone took the wheels. They cost me $7.50 a piece and the guy at the cash register was jealous that he didn't find them first haha.

In other random news, my friend Justin fixed my old Phoenix Gold amp. I guess it just needed some FETs or something. Electronics aren't my cup of tea

I just love this amp though because, well... look at it! That thing was hand built with pride in MERICA! Look at the American flags all over the boards. Love it. Noone makes anything like that anymore.

Back to the E36... one of the engine mount has completely failed as evidenced by a major clunk when accelerating in first gear. The clunk was the engine slamming back down after lifting off of the broken mount after peak torque lol. It has been doing that for years actually and I finally got the urge to figure it out once and for all.

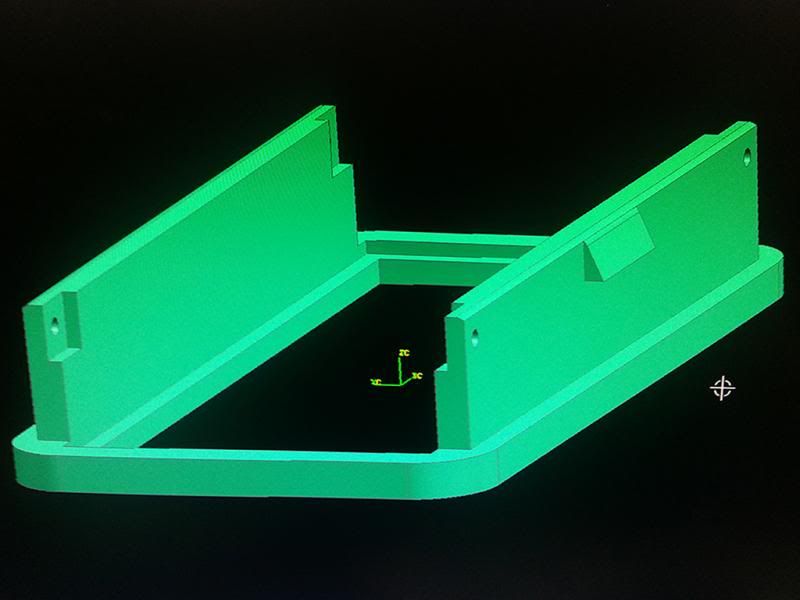

You know I wasn't going to spend the $60 for a new mount when I could just spend that money on a new lathe chuck to hold the large-ish material and make my own. So I set off to make my own mount. I wanted to test a concept. So I bought the chuck, came up with the conceptual design, finished up the final design/dimensions in a few nights, and then ordered up the materials and some hardware. A few days later and I had a 95% done, sweet mount. Thanks to Mr. Hersh for the Poly... do I still owe you for that dude? lol I'll take it off of the price of injectors if you want some

Here's the new 5" chuck vs the original 3" chuck

Some poly and some half-way finished parts in aluminum

90% finished mount next to the original fluid-filled mount

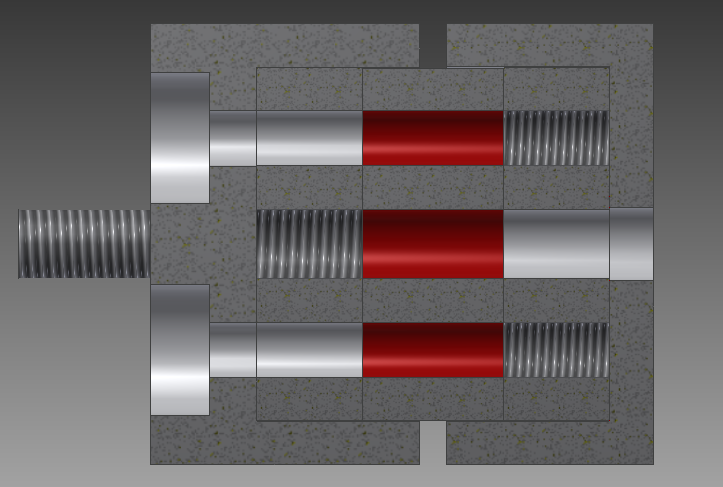

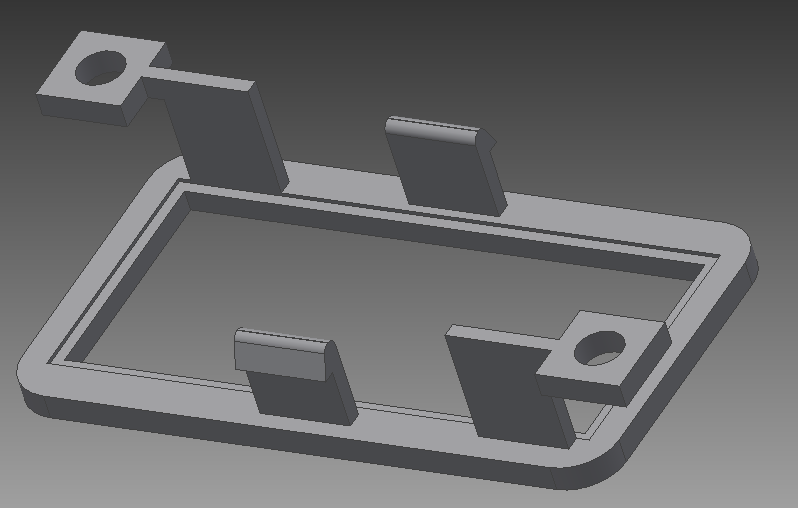

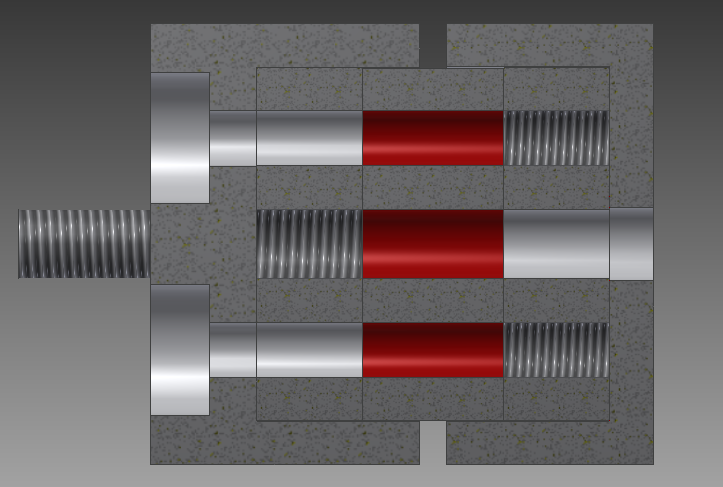

Now, this isn't a bolt-through design even though it might appear that it would be. Don't judge 'till you see and understand the x-section

Understanding how it works isn't all that easy. I struggled with it for quite some time, but you never have a condition where the poly isn't being engaged no matter how the mount is loaded (vibrations aren't just uni-directional).

I'm sure it'll be pretty hard, but it will do a lot more to damp vibrations than a bolt-thru or solid aluminum design would. Various durometers (and thicknesses once I iron some details out) of poly can be swapped in or out to tune damping. Also, if the poly gets worn, it is easy and cheap to replace.

Bolts are used in the two outer threaded areas and one large stud is used in the center threaded area. See if you can figure out how everything is loaded.

Lastly, here are some glamour shots (taken with my phone)

Here is the 635csi just before the worst rain/flooding I've seen in years. I almost got stranded on the way home. I managed to find a path that was less than 2 feet deep, but water still came inside the holes in the floor of the car lol. Good thing there is no carpet and I am in the midst of fixing it all. When I saw the sky I just thought, "Damn, I'm about to get soaked... IN the car."

On a slightly nicer day. My company had a sweet beach party with some good beverages and I was really able to appreciate this sight on the way back to the car later.

Oh, that reminds me, I lowered the car quite a bit after putting the spacers on. Unfortunately that side of the car still doesn't have center caps, but eh... still looks pretty good!

Lined up at Justin's place with the E34 and E46 too. E34 is jacked up for a new starter. It finally gave up the ghost at just under 360k miles (could be the second starter though) and years of making really weird noises while cranking LOL

And I just discovered today how much I like this shot!