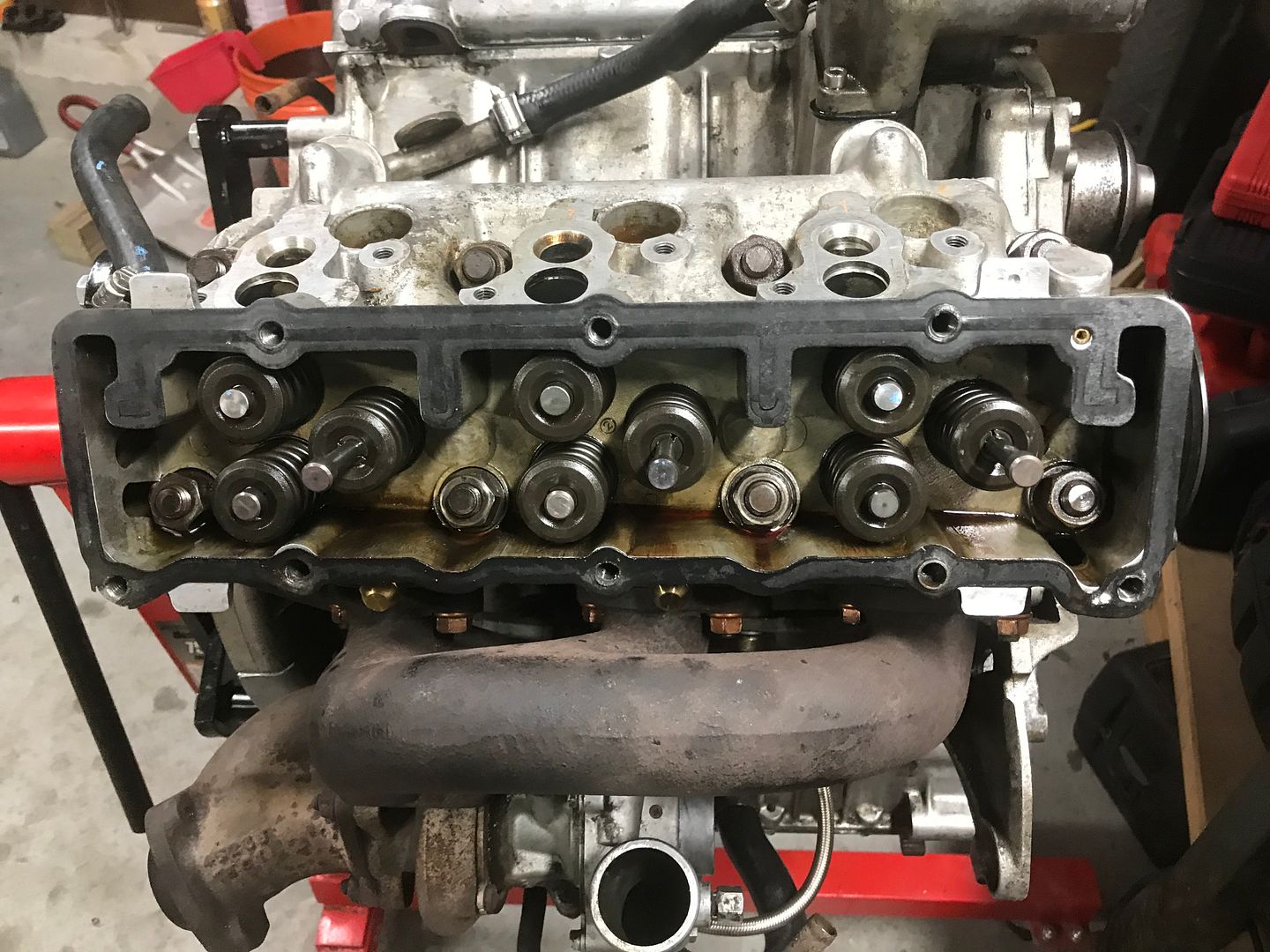

Deep into the most annoying part of this project yet - and that's saying something

These engines require that the clearance from the cams to the "cup" lifters be set to a close tolerance. The intake between 0.31 and 0.39 mm and the exhaust between 0.41 and 0.49mm.

To achieve this, you need to place the proper thickness shim on the end of the valve stem (one for exhaust, two for intake)

Mine were all wrong of course so I'm working on it now:

To make matters more annoying, you can only check the clearance with the cam box torqued down to the heads so I've had it on and off probably 10 times the last week or two while I slowly deal with this.

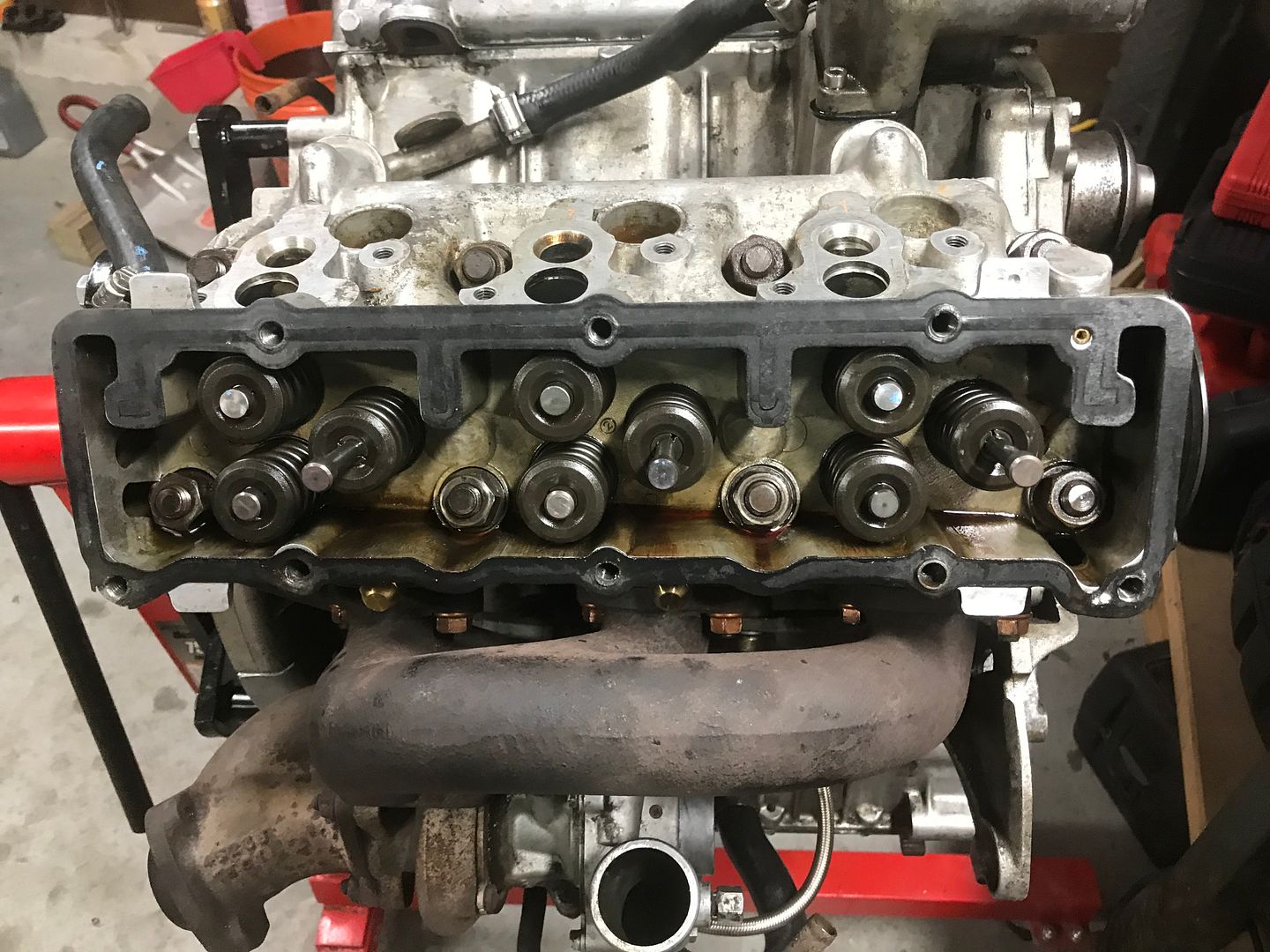

These engines are so weird. Turns out its the first ever 3 valve per cylinder engine ever mass produced (as well as the first twin turbo)

The image below shows the way the three valve works. Valve shims in red, cup lifters in blue, valve stems in yellow. The exhaust lobe only opens one exhaust valve so the stem is long and sits centered in the middle of the underside of the lifter cup. For the two intake valves, the lifter cup has thicker walls and the two valve stems hit opposite sides of the lifter cup on the thickened walls. So odd