i have a 5 gallon bucket with 3 gallons of solution in there. .75 gallons of battery acid, 2.25 gallons of distilled water. got 2 aluminum plates bent to the curvature of the bucket on the inside for the cathodes, and an aluminum rack that sits on the top of the bucket that i can suspend the parts from.

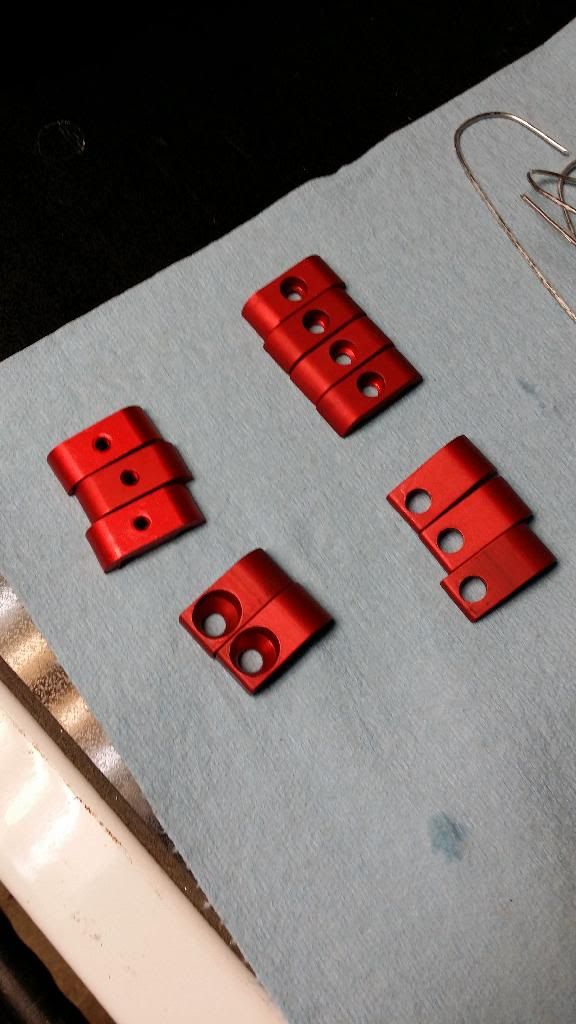

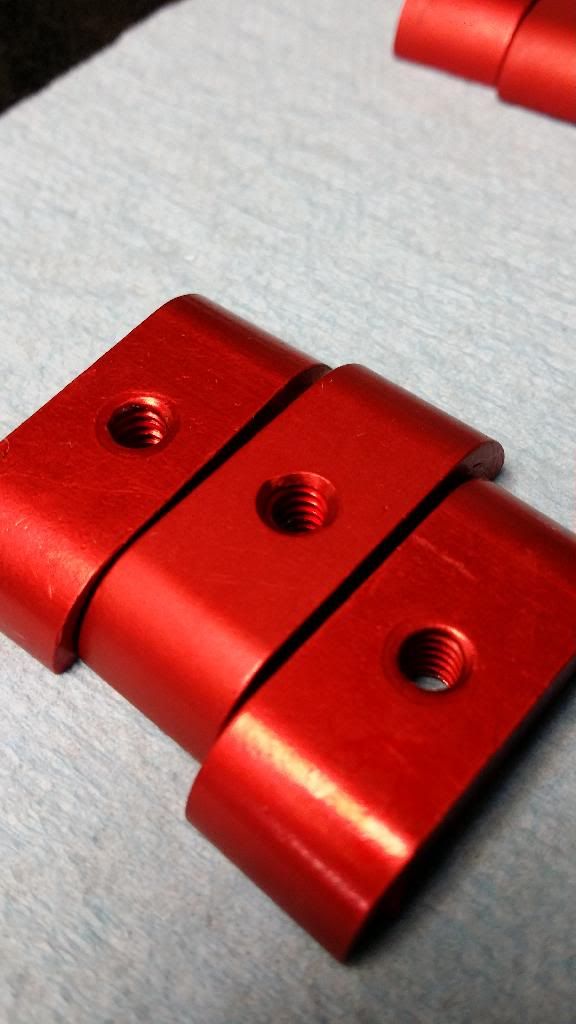

the parts are stripped, degreased, in an ultrasonic parts cleaner from harbor freight thats full of Greased Lightning....shit take anodizing right off aluminum by the way if anyones curious.

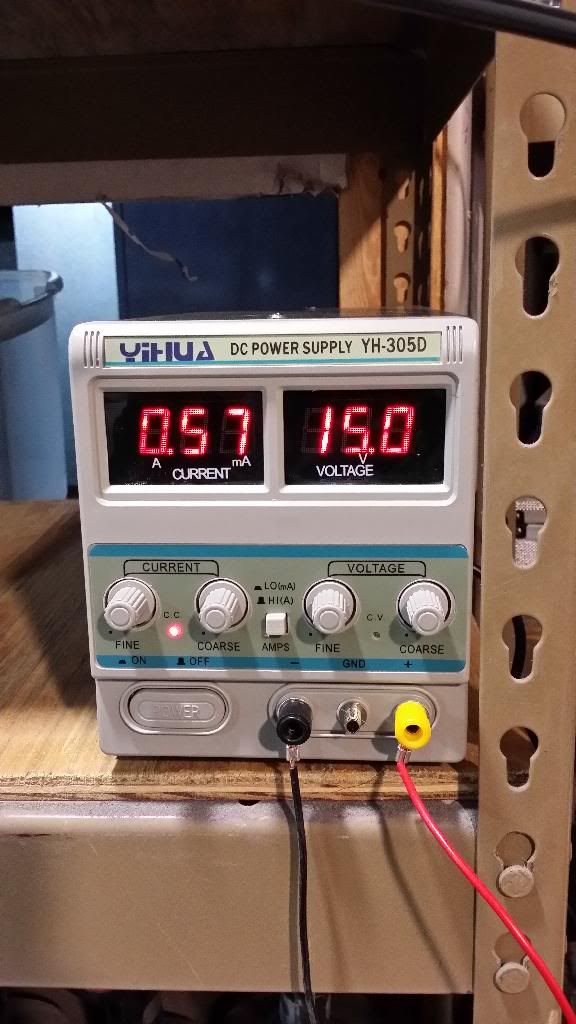

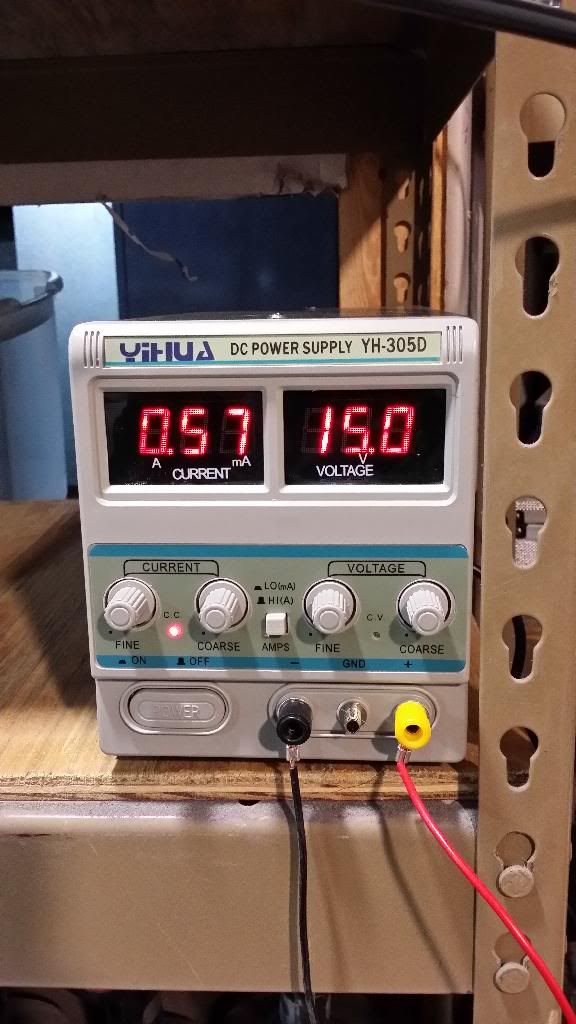

the power supply is a 0-30V 0-5amp ebay special, 70 bucks shipped from cali to my door.

then ive just got some other spare buckets that i hold the parts over and spray with distilled water in between tanks. other then that, i have an oster electric kettle that i use to heat the dye up to 140, then i have a pot on the stovetop that i use the oven for baking powdercoated stuff in to heat the sealer up to about 200 degrees. and thats the entire process. the parts sit in the ano bath for 2 hours, which is the longest part of the process.

This one time i built an...|-|Audi 90Q|-|2L20v|-|6765|-|Lugtronic|-|Street Tires|-|E85|-|10.7@136|-|...but then i parted it all out