Yes sir. I would just need something to go off of for dimensions.quattro wrote:Would you be able to do a pair of intake flanges for a 32v v8?

Search found 15 matches

- Thu May 09, 2013 9:12 am

- Forum: Member Products

- Topic: Nubworks DIY intake manifold parts

- Replies: 9

- Views: 26354

Re: Nubworks DIY intake manifold parts

- Mon May 06, 2013 9:24 am

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

- Tue Apr 30, 2013 3:27 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

- Sun Apr 21, 2013 12:05 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

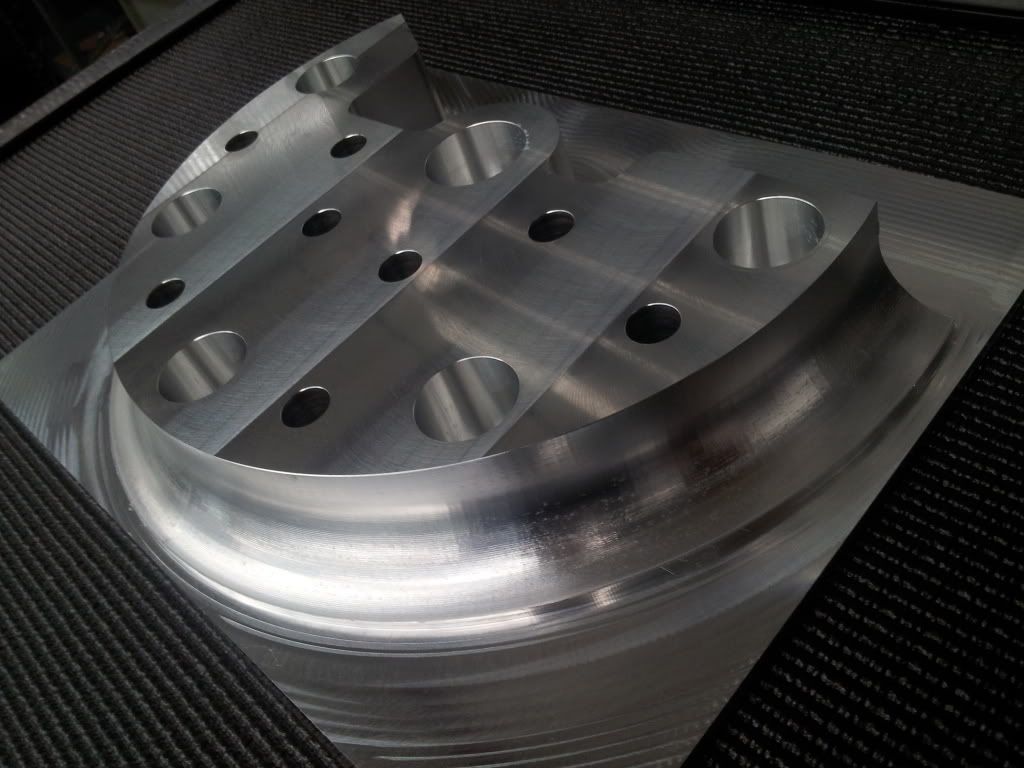

Thanks hank. Im really hoping it works out good. The original plan was to do it in 1 solid piece but the cost of material and a large radiused keyway cutter price was a little to high. Heres a couple pics of the finished die.

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130420_194209 ...

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130420_194209 ...

- Sat Apr 20, 2013 5:44 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

- Tue Apr 16, 2013 4:08 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

On the stock vc the bolts are visible from the outside. I think alot of the extra weight is coming from the material around the bolt holes. i was going for a "shaved" look

- Tue Apr 16, 2013 4:05 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

Im in charge of the mill dept at my day job so they pretty much let me do as i please for my personal projects. As of right now its 12 pounds. stock is 5 i believe. Im gonna throw it back in tonight to try and lighten it up some more.

- Tue Apr 16, 2013 2:07 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

It was a 2 day job. 8 hours the first day and about 7 hours the second day. Not counting programing and all the practice parts to get the pattern and the timing chain cover shape down perfectly

- Mon Apr 15, 2013 5:51 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

Thank you. Alot of time went into that one.

- Mon Apr 15, 2013 9:48 am

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

I had another fun project over the weekend for a 12v vr6. turned out pretty good i think.

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130413_102715_zpsf8db7e45.jpg

started with this 20x10x3 solid chunk of billet

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130413_111718 ...

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130413_102715_zpsf8db7e45.jpg

started with this 20x10x3 solid chunk of billet

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130413_111718 ...

- Tue Mar 26, 2013 11:51 pm

- Forum: Member Products

- Topic: Nubworks DIY intake manifold parts

- Replies: 9

- Views: 26354

Nubworks DIY intake manifold parts

Volkswagen 12v vr6

Standard plenum plate $165

http://i1352.photobucket.com/albums/q653/vdubluv_88/Nubworks-Theprojectpad/12vvr6standardplenumplate_zpsf41fd98d.jpg

Staggered plenum plate$300

http://i1352.photobucket.com/albums/q653/vdubluv_88/Nubworks-Theprojectpad/12vvr6staggardplenumplate ...

Standard plenum plate $165

http://i1352.photobucket.com/albums/q653/vdubluv_88/Nubworks-Theprojectpad/12vvr6standardplenumplate_zpsf41fd98d.jpg

Staggered plenum plate$300

http://i1352.photobucket.com/albums/q653/vdubluv_88/Nubworks-Theprojectpad/12vvr6staggardplenumplate ...

- Thu Mar 21, 2013 12:29 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

This ones from about a year ago but sure u guys will enjoy. Part of converting a 2003 mini cooper over to a electric race car.

1 off flywheel for a company called craven speed

http://i1352.photobucket.com/albums/q653/vdubluv_88/flywheel1_zps857a8dd1.jpg

http://i1352.photobucket.com/albums/q653 ...

1 off flywheel for a company called craven speed

http://i1352.photobucket.com/albums/q653/vdubluv_88/flywheel1_zps857a8dd1.jpg

http://i1352.photobucket.com/albums/q653 ...

- Wed Mar 20, 2013 10:55 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

Its nice to finaly be able to post somewhere without it getting flagged or deleted! If anyone is interested in having something made or even someone starting out in machining and want to ask some questions please do feel free to get in contact!

- Wed Mar 20, 2013 9:56 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Re: Nubworks 2013 CNC Madness!!!!

Thank you guys, greatly appreciated. I will try to update as frequent as possible

- Wed Mar 20, 2013 8:39 pm

- Forum: Projects

- Topic: Nubworks 2013 CNC Madness!!!!

- Replies: 39

- Views: 65959

Nubworks 2013 CNC Madness!!!!

Hows it going everyone? Figured id start a project thread on all the fun ive been up to this year.

First up, Doing a little intake manifold for my old ladys vr6..Inlets are 1/2 radius-ed with 10 degrees of taper.

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130320_165023_zpsfc186c5b.jpg ...

First up, Doing a little intake manifold for my old ladys vr6..Inlets are 1/2 radius-ed with 10 degrees of taper.

http://i1352.photobucket.com/albums/q653/vdubluv_88/20130320_165023_zpsfc186c5b.jpg ...